The Importance of Pharma Cold Chain

At the heart of the pharmaceutical industry is a commitment to innovation and groundbreaking change. However, what allows this cutting-edge work to make its maximum impact is the ability to distribute it across the globe reliably and in a way that safeguards viability and product potency.

This is where cold chain packaging plays an increasingly critical role in the industry, providing solutions for safely transporting and storing temperature-sensitive pharmaceuticals and life-saving medicines across every link in the supply chain.

Protection Across a Wide-Reaching Industry

With the evolution of pharmaceuticals, distribution networks are full of products with high-value active ingredients that require precise temperature requirements. As these biologics and specialty pharmaceuticals evolve, the need for temperature control has to evolve with it.

Across a broad spectrum of pharmaceutical sectors, each with its distinct temperature requirements, cold chain packaging solutions make a significant difference:

Biologics and Vaccines

As breakthroughs in biotechnology continue and the demand for temperature-sensitive biologics and vaccines rises, so does the need for solutions that protect product potency and reliability. From manufacturing through distribution, cold chain solutions help meet strict industry guidelines and standards and ensure the safe delivery of these critical products and therapies worldwide.

Specialty Pharmaceuticals

Due to the diverse ways people purchase pharmaceutical drugs today, it’s become increasingly complex to consistently maintain the right temperate and chemical composition of these specialty drugs in the supply chain. This high-dollar sector increasingly relies on cold chain packaging partners to help design custom solutions that protect its products against temperature variations and the company against waste and loss.

Clinical Trials and Research

Conducting research and clinical trials is a complex process that demands high levels of precision to ensure accuracy and safety. But that level of care is just as important when transporting and storing biological samples, vaccines, and other materials. A reliable cold chain packaging and logistics partner helps ensure regulations are met and the integrity of temperature-sensitive materials is preserved at every stage.

Blood and Plasma

These crucial components of healthcare are utilized daily for life-saving transfusions and clinical trials. Their survival, effectiveness, and shelf life depend on precise temperature-controlled storage and distribution. From the moment of collection to their final destination, these samples require just the right cold chain packaging solutions to maximize their effectiveness and shelf life.

Gene Therapies and Cell-Based Products

The fast growth of this sector has led to rising demand for cold chain packaging to preserve the viability and functionality of these advanced-level therapeutic products. The manufacturers in this space need logistics partnerships to maintain the necessary standards while enhancing their ability to distribute their products across even longer distances and parts of the world that haven’t typically had access to them.

Pharma depends on KODIAKOOLER® solutions.

At KODIAKOOLER®, our top priority is maintaining the integrity of the products you’ve worked hard to manufacture. Our commitment to innovation and performance is backed by our continued reinvestment in our capabilities, extensive testing, and our proven pre-qualified shippers. We ensure that our packaging meets your standards and the standards of different accreditations like those of ACHC and URAC.

Our temperature-controlled packaging, advanced insulation, and customizable thermal protection options suit various pharmaceutical sectors, regardless of sensitivity or how far the product travels.

Foam Solutions

Our reliable and economical EPS foam coolers have been a go-to option for the pharmaceutical industry for years due to their durability, shock absorption, moisture resistance, and proven temperate control. Now available to be manufactured with biodegradable resin, this time-tested option has never been more sustainable.

Natural Fibers

Our natural fiber Kotton liners and mailers have been tested by ISTA certified professionals to deliver superior insulation and temperature control that is just as reliable as traditional foam. This recyclable and biodegradable product proves that you can reduce your environmental footprint without reducing quality or increasing costs.

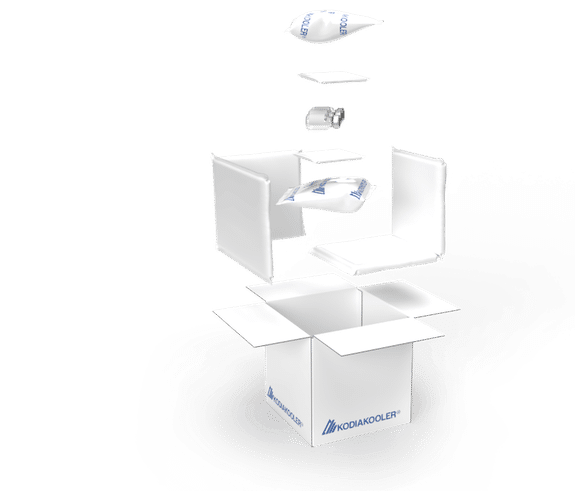

Pre-qualified Shippers

Beyond our custom packaging capabilities, we also have a selection of ready-to-go, pre-qualified shippers designed to protect a wide variety of pharmaceutical products. These solutions have already been tested extensively and meet the accreditation standards of ACHC, URAC, and others.

Shipping pharmaceuticals is complex and costly. By understanding the specific scopes, processes, and materials involved, you can make informed choices to safeguard your products throughout the supply chain. Our strategic solutions have been tested by certified third parties to preserve the integrity of your products. Contact us today to learn more about how KODIAKOOLER can be a strategic partner to your organization.